Everything You Need to Know About Solar System Earthing

When we think of solar systems, the first things that come to mind are shiny panels on rooftops and the money saved on electricity bills. But behind every safe and reliable solar plant lies something less visible but equally important

Earthing may not sound exciting, but it’s the foundation of safety in any solar installation. It protects your home, your equipment, and most importantly, your family from electrical faults or lightning strikes. Without proper earthing, even the best solar setup can turn risky.

In this blog, we’ll break down what earthing is, why it’s crucial in solar systems, the different types used, and the standards you need to follow. Whether you’re planning a home installation or a large commercial project, understanding earthing will help you make smarter and safer solar choices.

What is Earthing?

Earthing, also called grounding, is the process of connecting electrical equipment to the earth using a conductor. The main purpose is to provide a safe path for excess current in case of faults or lightning strikes. In solar installations, earthing ensures that both people and equipment remain protected from unexpected electrical hazards.

When a solar system is installed, multiple electrical components like inverters, modules, and mounting structures are used. Each of these has the potential to carry fault current if something goes wrong. By creating a proper earthing connection, this unwanted current is directed into the ground rather than flowing through equipment or humans.

Simply put, earthing is a safety backbone for every solar setup. Without it, even the most advanced solar panels or inverters can become unsafe over time.

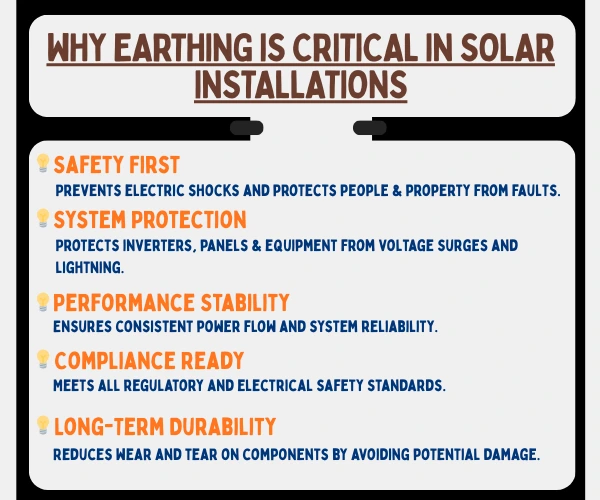

Importance of Earthing in Solar Systems

The role of earthing goes far beyond just meeting safety rules. It has direct benefits for system performance and longevity.

- Safety First: Prevents electric shocks and protects people & property from faults.

- System Protection: Protects inverters, panels & equipment from voltage surges and lightning.

- Performance Stability: Ensures consistent power flow and system reliability.

- Compliance Ready: Meets all regulatory and electrical safety standards.

- Long-term Durability: Reduces wear and tear on components by avoiding potential damage.

Types of Earthing Needed in Solar Installations

In solar projects, more than one type of earthing may be required. Each plays a unique role in ensuring safety and performance. The main type of earthing we focus on is chemical earthing.

Chemical Earthing

Chemical earthing is one of the most preferred methods for modern solar installations because it provides long-term stability and low maintenance. It uses salt and charcoal and use of specially developed compounds that retain moisture and ensure consistent conductivity.

In this method, an electrode is placed in the ground and surrounded by a chemical mixture. This compound prevents the soil around the electrode from drying out and reduces corrosion of the electrode, which means the earthing system lasts much longer.

For solar systems, chemical earthing is highly effective because:

- It maintains a low and stable resistance over many years.

- It requires less frequent watering or maintenance compared to traditional methods.

- It performs well even in areas with rocky or sandy soil where normal earthing may fail.

- It ensures better safety against lightning strikes and electrical surges that could damage your solar equipment.

While the initial cost may be slightly higher, the long-term performance and safety benefits make it a worthwhile investment.

Some other types of earthing include:

Equipment Earthing

- Protects metal parts like module frames, mounting structures, and inverter casings.

- Ensures no dangerous current remains on exposed surfaces.

- Connected via copper or GI (galvanized iron) conductors.

Lightning Protection Earthing

- Directs lightning strikes safely into the ground.

- Protects panels and rooftop structures from damage.

- Essential in areas prone to thunderstorms.

Functional Earthing

- Provides a reference point for electrical systems.

- Stabilizes system voltage and prevents over-voltage risks.

- Used mainly for inverters and sensitive electronics.

Neutral Earthing

- Protects against overloads by ensuring current safely returns to the ground.

- Often used in larger commercial or industrial setups.

Each of these earthing types is critical, and skipping any can lead to safety or efficiency issues in solar systems.

Earth Cables in Solar Systems

The effectiveness of earthing depends heavily on the cables used. These cables connect solar equipment to the earth pit.

- Material: Usually copper or aluminum, as they have high conductivity.

- Size: The thickness of the cable depends on the system size and the short-circuit.

- Color: Green or green-yellow insulation is commonly used to identify earth cables.

- Durability: Must withstand outdoor conditions, UV rays, and moisture.

- Routing: Should be kept as short and straight as possible to minimize resistance.

Using low-quality cables or incorrect sizes can defeat the purpose of earthing. Hence, choosing the right earth cables is as important as installing panels or inverters.

Earthing Standards to Be Followed

Earthing isn’t optional; it must follow set guidelines to ensure safety and compliance. In India and worldwide, several standards apply to solar system earthing.

- IEC Standards (International Electrotechnical Commission): Provide global guidelines on earthing and safety.

- BIS Standards (Bureau of Indian Standards): Local rules that govern earthing practices in India.

- CEA Guidelines (Central Electricity Authority): Cover earthing requirements for renewable energy projects.

- IS 3043: Indian code of practice for earthing.

Key requirements include:

- Earth resistance should generally be less than 1 ohm for safety.

- Use of corrosion-resistant electrodes like copper-bonded rods or GI strips.

- Lightning protection must be installed for larger rooftop plants.

Following these standards ensures your system passes inspections and avoids penalties.

Maintenance of Earthing in Solar Systems

Just like solar panels need cleaning, earthing needs regular maintenance. Over time, soil conditions, weather, and usage can affect earthing performance.

Key Maintenance Practices:

- Routine Testing: Earth resistance should be tested every 6-12 months.

- Soil Treatment: Adding charcoal and salt to the earth pit helps maintain low resistance.

- Check for Corrosion: Replace damaged or rusted electrodes and wires.

- Tight Connections: Ensure all connections are torqued and secure.

- Visual Inspections: Look for exposed or broken cables that may affect safety.

Proper maintenance ensures earthing works effectively during faults or lightning strikes. Neglecting it can put both people and the system at risk.

Conclusion

While panels and inverters grab most of the attention, earthing quietly ensures the safety and smooth functioning of the whole system. From preventing shocks to protecting costly equipment, its role is undeniable.

At Smart Roof Solar, we go beyond just installing solar panels; we ensure every part of the system, including earthing, meets strict safety standards. Our team uses the best materials and practices to give you a secure, long-lasting solar setup.

FAQs

Q1. How deep should an earthing pit be for a solar installation?

Ans: Typically, the earthing pit should be 3 to 4 meters deep, depending on soil resistivity.

Q2. What is the cost of earthing in a solar project?

Ans: Average cost of earthing is ₹6,000 per pit based on materials and the type of earthing used.

Q3. How often should solar earthing be checked?

Ans: Every 6 to 12 months, depending on environmental and system conditions.

Q4. Which electrode is best for earthing in solar setups?

Ans: Copper-bonded rods are preferred for their conductivity and corrosion resistance.

Q5. How is industrial solar earthing different from residential?

Ans: Industrial setups use heavier conductors, multiple pits, and advanced surge protection.

Suggested Articles

Is it Wise to Switch to Solar in India?

India has become a hot-selling solar market and people are interested in installing solar systems in their homes as well as in industries and factories.

Renewable Energy Hits New Heights: 440 GW Capacity in 2023

Learn how global renewable energy capacity is set to surpass 440 GW in 2023, marking record growth and a major shift toward clean, sustainable power.

Sizes and Features of Solar Panels available in Delhi/NCR

With the advancement in technology, the sizes of the solar…

UP Discoms Propose 9.21% Electricity Tariff Hike for 2015-16

Uttar Pradesh Discoms propose a 9.21% increase in electricity tariffs for 2015-16, impacting residential, commercial, and industrial consumers across the state.

Indian solar market flooded with various Inverters – User discretion required

With Indian government’s target of 100 GW by Solar power,…

Can Industries/Factories run all Heavy Machines and Motors on Solar System?

Discover how using solar for heavy machines can power industrial equipment reliably and cost-effectively for greener operations.

Challenges in Module Supply and Policy Slow India’s Solar Projects

India’s utility-scale solar projects face delays due to module supply shortages and policy challenges, impacting the growth of renewable energy.

Is your Solar PV Rooftop System Safe and Protected?

In the competitive market of Solar PV Rooftop industry…

India’s Renewable Energy Revolution: The Role of Agrivoltaics

Explore how agrivoltaics is driving India’s renewable energy revolution by combining solar power with agriculture for sustainable growth.

Financing made easy for the Rooftop Solar Projects

Solar roof top is expected to get a big push with the new…